What Are the Most Innovative Solutions for Small-Batch Production?

Nowadays, small-batch production is more common than ever. In an environment where businesses are increasingly focusing on customization and flexibility, innovative solutions that can handle small-batch production become essential.

Manufacturing projects in Gujarat have also been quick to adopt these innovative solutions, leveraging technology and automation to optimize their small-batch production processes and stay competitive in the market.

The purpose of this article is to explore cutting-edge solutions that can redefine the game in this niche.

Solutions for Small-Batch Production

Understanding the Challenges

Small-batch production comes with its own set of challenges. Traditional manufacturing processes often struggle to adapt to the varying demands, resulting in inefficiencies and increased costs.

The need for specialized tooling, longer setup times, and the lack of economies of scale can pose significant obstacles for businesses aiming to thrive in this environment.

Embracing Digital Transformation

The key to overcoming the challenges lies in embracing digital transformation.

Incorporating advanced technologies such as Artificial Intelligence (AI) and the Internet of Things (IoT) can revolutionize small-batch production.

AI-driven predictive maintenance can minimize downtime, while IoT-enabled sensors provide real-time data for improved decision-making.

In this field, 3D printing has also played a significant role. It allows for rapid prototyping and cost-effective production of small batches. Besides reducing lead times, this also allows for greater design flexibility.

Lean Manufacturing Principles

Adopting lean manufacturing principles is crucial for optimizing small-batch production. Streamlining processes, minimizing waste, and enhancing overall efficiency are at the core of lean manufacturing.

By implementing Kaizen methodologies, businesses can continuously improve and adapt to changing demands seamlessly.

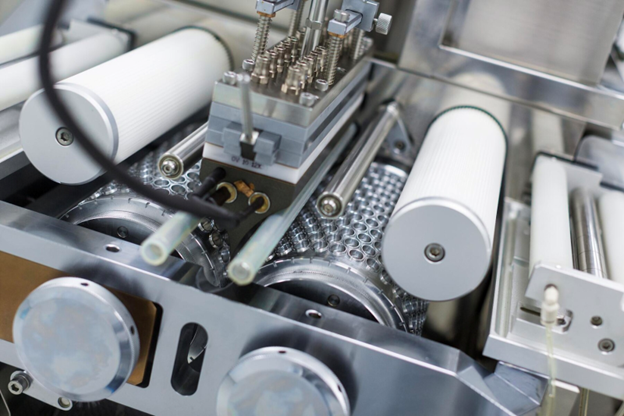

Robotics and Automation

The integration of robotics and automation is indispensable for small-batch production. Automated systems can handle repetitive tasks with precision, ensuring consistent quality while freeing up human resources for more complex and creative endeavors.

Collaborative robots, or cobots, work alongside human operators, creating a harmonious blend of human ingenuity and machine precision.

Cloud-Based Manufacturing Execution Systems (MES)

Cloud-based MES solutions enable real-time monitoring and control of production processes, even in small-batch scenarios. This technology provides manufacturers with valuable insights, allowing them to optimize workflows, track performance, and make data-driven decisions. The result is improved overall efficiency and resource utilization.

Collaborative Robotics (Cobots)

Collaborative robots, or cobots, are designed to work alongside human operators. In small-batch production, where tasks may vary, cobots offer flexibility and increased safety. Their user-friendly interfaces and adaptability make them valuable assets in optimizing production processes without compromising on precision.

Supply Chain Resilience

Successful small-batch production depends on a resilient supply chain. Diversifying suppliers, utilizing local resources, and employing blockchain technology for transparent and traceable transactions can enhance the reliability and flexibility of the supply chain.

Environmental Sustainability

In the era of increasing environmental awareness, small-batch production can benefit from adopting sustainable practices. From sourcing materials responsibly to optimizing energy consumption, businesses can carve a niche by aligning with eco-friendly initiatives. Consumers are increasingly valuing products that are not only unique but also produced with a commitment to environmental responsibility.

Conclusion

In conclusion, the future of small-batch production lies in embracing innovation and adopting a holistic approach. The amalgamation of digital transformation, lean manufacturing, robotics, and sustainability practices can catapult businesses into a new era of efficiency and competitiveness.

The ever-evolving landscape requires a proactive stance towards change, and those who leverage innovative solutions will undoubtedly lead the way.

Ready to revolutionize your production processes? Consult with VMS Consultants – Your partners in Engineering, Architecture, and Project Management Services.

Elevate your operations with our expertise. Contact us today for customized solutions that drive success.