Structural Design for Wind Loads: Ensuring Industrial Resilience

General Introduction

In the realm of industrial construction, the structural design for wind loads is an important consideration. Industrial structures, whether they house manufacturing units, large warehouses, or energy facilities, must be engineered to withstand the forces of nature.

Among all these forces of nature, wind loads stand out as a significant challenge. In this article, we will look into the crucial aspects of designing industrial buildings and structures to withstand wind loads, ensuring safety, longevity, and operational efficiency.

Understanding the Impact of Wind Loads

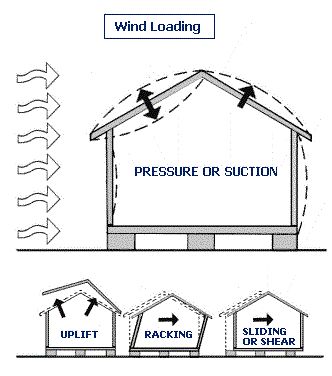

Before diving into the specifics of structural design, it is of vital importance to grasp the dynamics of wind loads. Wind loads exert lateral forces on industrial structures, posing a threat to their stability and integrity. The magnitude of these forces depends on various factors, including the speed of the wind, duration, wind direction, and shape of the building. High winds can lead to catastrophic failures if not adequately accounted for in the structural and building design processes.

Key Factors in Wind Load Analysis

Below are some of the most crucial factors to be taken into account while designing an industrial structure.

1. Wind speed and direction:

Wind speed is one of the most important factors in determining the magnitude of wind loads. Construction engineers must analyze historical wind data for the specific location where the industrial building will be built. Additionally, wind direction plays a crucial role too, as the shape and orientation of the industrial facility can affect wind pressure distribution.

2. Terrain and topography:

The surrounding terrain and topography can significantly influence the patterns of wind. Structures situated in open plains experience different wind conditions than those located in urban environments or near water bodies. Analyzing these factors helps structural engineers refine load calculations.

3. Building Shape and Geometry:

The shape and geometry of the industrial building play a pivotal role in analyzing the wind load. Tall and slender structures are more susceptible to wind-induced vibrations and lateral forces, requiring special attention in their structural design.

4. Building Codes and Standards:

Compliance with local building codes and international standards is very important. Building codes provide guidelines for designing structures to withstand wind loads specific to the area, ensuring safety and reducing risks to a great extent.

Designing for wind loads

1. Wind load calculations:

The primary step in designing structures for wind loads is to calculate the expected wind loads on the structure. Structural engineers implement test elements such as wind load maps, wind tunnel tests, and computational simulations to determine these loads accurately. These calculations and analyses consider factors such as wind speed, direction, and the shape of the structure.

2. Selecting Materials:

The choice of building materials is crucial in designing industrial structures for wind loads. Civil engineers must select construction materials that are not only strong and durable but also resilient to environmental factors. Steel and reinforced concrete (RCC) are commonly and extensively used for the construction of industrial structures due to their high strength- to-weight ratios.

3. Aerodynamic Design:

To reduce resistance due to wind and minimize wind loads, construction engineers often employ aerodynamic design techniques. This may include shaping the structure to minimize wind drag or installing wind deflectors and streamlined elements to redirect wind flow.

4. Foundation Design:

A robust building foundation is essential for withstanding wind loads. Engineers design such foundations that can distribute the wind-induced forces evenly throughout the structure, preventing excessive stresses at specific points in the building.

5. Structural Redundancy:

Incorporating redundancy into the structural design is an important safety measure. Redundant structural elements ensure that even if one part of the structure fails, others can still provide support, eliminating catastrophic collapses.

6. Damping Systems:

For tall and slender industrial buildings, damping systems can be employed to reduce wind- induced vibrations. These systems, such as tuned mass dampers or viscous dampers, absorb and dissipate energy, improving the stability of structures.

Wrapping Up

Industrial buildings must be designed with proper attention to wind loads to ensure their safety, resilience, and longevity. Wind load analysis, selection of building materials, aerodynamic design, and adherence to building codes and standards are fundamental aspects of this process. By considering these factors and implementing them into the design phase, engineers can build industrial structures that stand tall against the forces of nature, guaranteeing safety for both occupants and assets.

As the importance of sustainability and resilience in industrial construction continues to grow, the role of wind load analysis and structural design becomes increasingly vital. By investing in a well-thought-out wind load-resistant design, industries can safeguard their operations and assets against the unpredictable forces of the wind.