Industrial Floors for Piles Supported Slab, Ground Supported Slabs

Industrial floors

Floors are one of the important component of any industrial project be it a warehouse or a process industry. Amongst various construction activities, an important role is reserved to Industrial floors. Floor should serve the desired purpose like resistance, flatness, levels, etc. and hence it has to be designed as performance based component and not just simply as a structural component.

Internationally various codes are available that guides the design of floor. American Concrete Institute has published ACI 302, the concrete society – UK has published TR-34 and many more institutes have defined their own standards for grade slab. In India TR-34 is the most commonly referred and used.

Aspects need to define for delivering the required floor:

- Design of grade slab considering the type of load floor is expected to – i.e. uniformly distributed load, Dynamic loads, Point loads, MHE (Material Handling Equipment) movement loads, etc.

- Location of joints are planned and detailed based on the layouts

- Surface regularity (flatness and levelness) , floor surface characteristics requirements like hardness

- Type of MHE to be used – this aspect is important specially for warehouses because floor has to meet the requirements of MHE manufacturer for hassle free operations

- Floor surface i.e. abrasion resistant, slip resistant, chemical resistant, etc.

- Appropriate Construction methodology

Design of Grade slab

Grade slabs are either designed as:

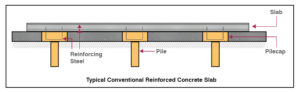

1.Piles supported slab

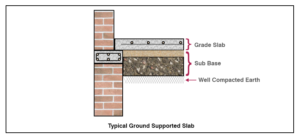

2.Ground supported slabs

Soil investigation is the first step towards design of Grade slab for the required criteria defined above. For Ground supported slabs, the design requires k values either derived from CBR values or from Plate load test. It is better to verify the k values by Plate load test. For Pile supported slabs, all the parameters required determining the load –bearing and deflection has to be carried out.

Pile supported floors are mostly used when the ground bearing conditions are inadequate for ground supported floor and in this case ground only acts as place in form work for grade slab.

Components of Ground supported slabs are

- Sub-grade – provides uniform support to the slab and should be well-compacted.

- Sub-base – transmit load from slabs to the sub-grade and provide levelled platform for construction of slab

- Membrane – It reduces the friction between the slab and sub-base and also acts as vapour barrier.

- Insulation – For building having temperature controls requires a layer for insulation to protect sub-base from temperature variations.

- Slabs – This is the homogenous serviceable layer on which the loads will be directly applied and has to be designed for its surface requirement & level requirements along with to carry intended load.

Joints in grade slab:

Joints are provided in grade slab to relieve tensile stress induced by temperature difference and to accommodate breaks in the construction and to isolate

In steel reinforced grade slabs, Joints are classified as follows:

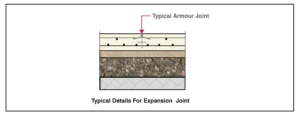

- Expansion/Free movement joint – These are designed to provide minimum restraint to horizontal movements of slabs caused by temperature changes in the grade slab. TR 34 states that “Expansion joint is not used in internal floors, except those subject to above ambient temperatures and to large temperature fluctuations”.

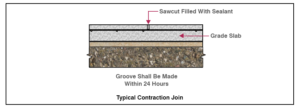

- Contraction/Restrained joint – These joints are created by saw cutting at regular intervals between the construction joints. The function of these joints is to reduce potential for random cracking in the slab caused by shrinkage due to evaporation of moisture from the slab concrete. The joint spacing should be 24 to 36 times the thickness of the slab.

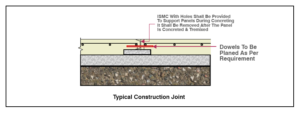

- Construction /Tied joint – These joints are provided to facilitate break in construction. The joint is provided with cross sectional area of steel high enough to prevent opening of joint.

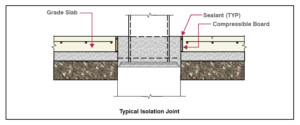

- Isolation joint – These joints are provided in slab to isolate slab from machinery foundation that are subject to vibration, fixed elements such as wall/columns, etc. Isolating material should extend throughout the full depth of the slab and sealed with sealant at the top to prevent any ingress into the slab.

Joints have to be located and designed properly as they may turn to the source of potential problem in grade slabs.

Surface Regularity Requirements

Depending upon requirements of MHE the surface regularity has to be provided to the grade slabs. Based on movement of MHE i.e. Free Movement (FM) or Defined Movement (DM) TR-34 has categorized floor class and their tolerances.

In Free Movement (FM) areas MHE can move randomly where as in Defined movement (DM) areas MHE can move in defined path normally associated with high level stacking with very narrow Aisle (VNA):

For Free Movement, floors are categorized in FM1, FM2, FM3 and FM4. Surface regularity in these floors is defined in two ways- flatness and levelness. TR-34 (4th edition) have specified tolerance limit for controlling level (Property E) and flatness (Property F) in table 3.1 as shown.

For Defined Movement, floors are categorized as DM1, DM2 and DM3. DM1, DM2 and DM3 floor is defined for racking top beam height over 13 m, 8-13 m and upto 8 m respectively.

Floor Finish Requirements

Depending upon the type of industry floor finish has to be selected. Like industry dealing into solvents or chemical requires acid resistant flooring, industry dealing into wet areas requires anti-skid floor, for food and pharma hygiene and at times temperature resistance is of utmost importance. Many challenges are faced by experts to define floor finish due to varied requirements of different industries and different formulations available in the market by different companies. The few elements that have to define before selecting type of floor finish are:

- Traffic: Type and volume of traffic anticipated for the floor

- Purpose: Define the purpose of finish if it is Hygiene, chemical resistance, temperature resistance, anti-skid, cold storages, antistatic, etc.

- Economy: It is advisable to select the floor finish that fit’s the purpose than cost of the finish. It is important to consider maintenance and cleaning cost instead of only considering installation cost for defining the economical option.

Construction Methodology

It is critical to define the construction methodology during the design stage itself. Construction methodology will define the floor joint layout and how the floor is reinforced. Appropriate construction methodology has to be selected to achieve require surface regularity and productivity. There are basic two methods of construction:

- Long Strip

- Large Area Pour

In Long Strip construction, long strips of around 5 m are laid. This method is commonly used for areas requiring high level of surface regularity.

In Large area Pour method large pour of around 1000 to 1500 m2 of slab is cast in a day increasing the productivity. It helps in reducing number of joints. Laser screeds are used to control the surface regularity. However, in this type it is difficult to achieve high level of surface regularity.

With increasing demand of surface regularity and productivity various screeds are available in the market to cater to the need which has opened up industry flor flooring specialists in the market.

We at VMS have served to various kinds of specialized industries including Agro & food, automobile, textile, packaging, Consumables, heavy engineering, Warehouses, etc and have designed grade slabs considering industry specific requirements.

Call engineering consultant firm in India at +91 – 79 – 40236 236, Email at contact@vmsconsultants.com

Website – https://www.vmsconsultants.com/

Free Consultation – https://www.vmsconsultants.com/free-consultation/

Inquire us online – https://www.vmsconsultants.com/contact-us/