How to Plan an Electronics Manufacturing Plant: Step-by-Step Guide

Setting up an electronics manufacturing plant in India is a strategic move with long-term potential. With rising domestic demand, global supply chain shifts, and strong government incentives, India is becoming a preferred destination for electronics production.

But success depends on careful planning, smart execution, and expert guidance—especially when dealing with complex facility requirements.

Step 1: Define Your Product and Market

The first step is identifying the specific electronics you plan to manufacture – whether they are consumer electronics, PCBs, IoT components, or electric vehicle electronics. This decision will shape everything from layout to machinery.

Conduct market research to understand demand, competition, and pricing. A clear product strategy helps in estimating production volumes and aligning with the right supply chain partners.

Step 2: Create a Business and Facility Plan

A detailed business plan is essential. It should include investment estimates, staffing needs, raw material sourcing, and production goals. Alongside this, develop a facility plan that outlines space requirements, workflow, and future scalability.

Engaging a manufacturing plant design consultant at this stage ensures your layout supports both operational efficiency and regulatory compliance.

Step 3: Choose the Right Location

Location impacts logistics, labor availability, and access to utilities. Industrial zones, SEZs, and electronics manufacturing clusters offer infrastructure and incentives.

Look for areas with reliable power, water, and skilled workforce. Cities like Ahmedabad, Pune, and Chennai are emerging hubs for electronics manufacturing due to their connectivity and policy support.

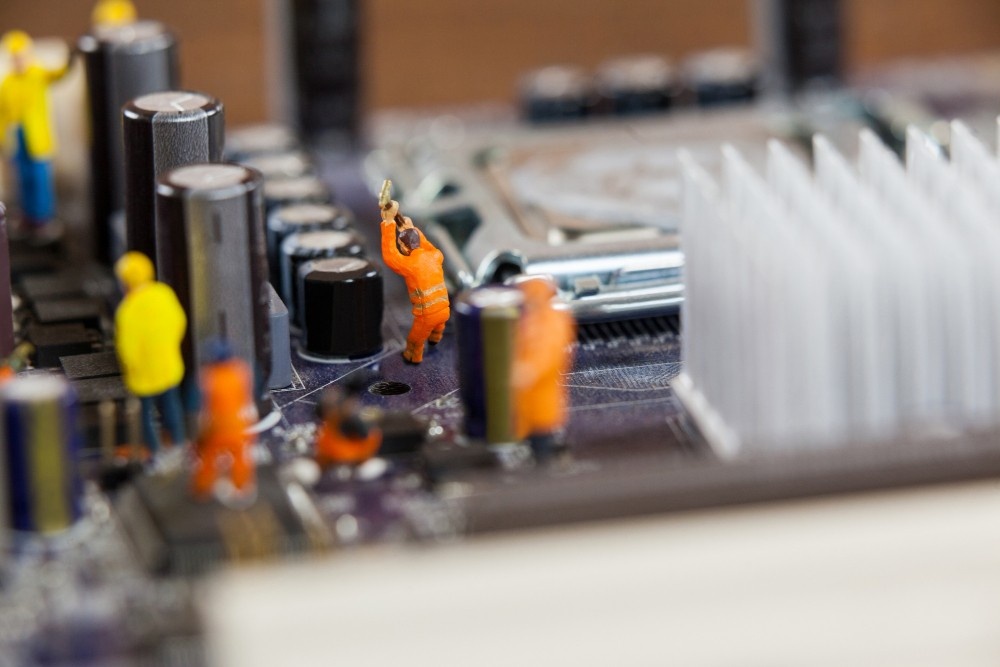

Step 4: Design the Facility for Efficiency and Safety

Factory layout should support lean manufacturing principles. Plan for assembly lines, testing labs, ESD-safe zones, and storage areas. Include provisions for future automation and expansion.

Safety and compliance are critical. Ensure fire exits, ventilation, and ergonomic workstations are part of the design. Electronics manufacturing plant facility setup services from experienced consultants can help integrate these elements seamlessly.

Step 5: Procure Machinery and Equipment

Choose machinery based on your product type and production scale. For PCB assembly, you’ll need pick-and-place machines, reflow ovens, and testing tools. For consumer electronics, consider automated assembly and packaging systems.

Plan for both current needs and future upgrades. Equipment layout should minimize material movement and support smooth workflow.

Step 6: Hire and Train Your Workforce

Electronics manufacturing requires skilled technicians, engineers, and quality control experts. Tap into local talent pools and government training programs like Skill India.

Invest in onboarding and continuous training to ensure your team can operate machinery, follow safety protocols, and maintain quality standards.

Step 7: Ensure Regulatory Compliance

Register your business and obtain necessary licenses—MSME registration, GST, factory license, and Import Export Code (IEC) if applicable. Environmental clearances and labor law compliance are also essential.

Working with a manufacturing plant design consultant helps navigate these approvals efficiently and ensures your facility meets all legal requirements.

Step 8: Integrate Technology and Automation

Modern electronics plants benefit from Industry 4.0 technologies—IoT sensors, digital twins, and automated quality control. These tools improve productivity, reduce errors, and support data-driven decision-making.

Start with scalable automation and build toward smart factory capabilities. Consultants like VMS can help integrate these systems into your facility design.

Step 9: Plan for Quality Control and Testing

Quality assurance is non-negotiable in electronics. Set up dedicated testing zones, inspection protocols, and documentation systems. Use automated testing tools where possible to ensure consistency.

ISO certifications and adherence to global standards improve credibility and open doors to export markets.

Step 10: Launch and Optimize

Before full-scale production, run pilot batches to test systems and workflows. Monitor performance, identify bottlenecks, and make adjustments.

Post-launch, focus on continuous improvement—optimize processes, reduce waste, and upgrade technology. A good facility design allows for easy reconfiguration and scaling.

Take the Next Step Toward Smart Manufacturing

Setting up an electronics manufacturing facility in India is a high-potential venture that requires precision, planning, and professional support. From layout design to compliance and automation, every step matters.

Looking to build a future-ready electronics facility?

Partner with VMS Consultants for expert engineering, architecture, and project management services tailored to electronics manufacturing.