How Much Space Do Different Manufacturing Processes Actually Require?

One of the most common questions factory owners ask at the planning stage is deceptively simple: How much space will my manufacturing process actually need?

In practice, this is also one of the most misunderstood aspects of factory development. Many projects either underestimate space and struggle operationally or overestimate it and lock capital into underutilised built-up areas.

In the Indian manufacturing context, space planning is not just about fitting machines into a building. It is about balancing production flow, safety, utilities, storage, compliance, and future growth. Understanding realistic space requirements for different manufacturing processes is critical to building an efficient and scalable facility.

Why Space Planning Cannot Rely on Thumb Rules Alone?

It is tempting to use broad benchmarks such as “square feet per machine” or “area per employee.” While these may offer a starting point, they rarely reflect real operational needs.

Space requirements vary based on:

- Type of manufacturing process

- Level of automation

- Material flow complexity

- Quality and inspection requirements

- Regulatory and safety norms

Two factories producing the same product can have very different space needs depending on how the process is designed and sequenced.

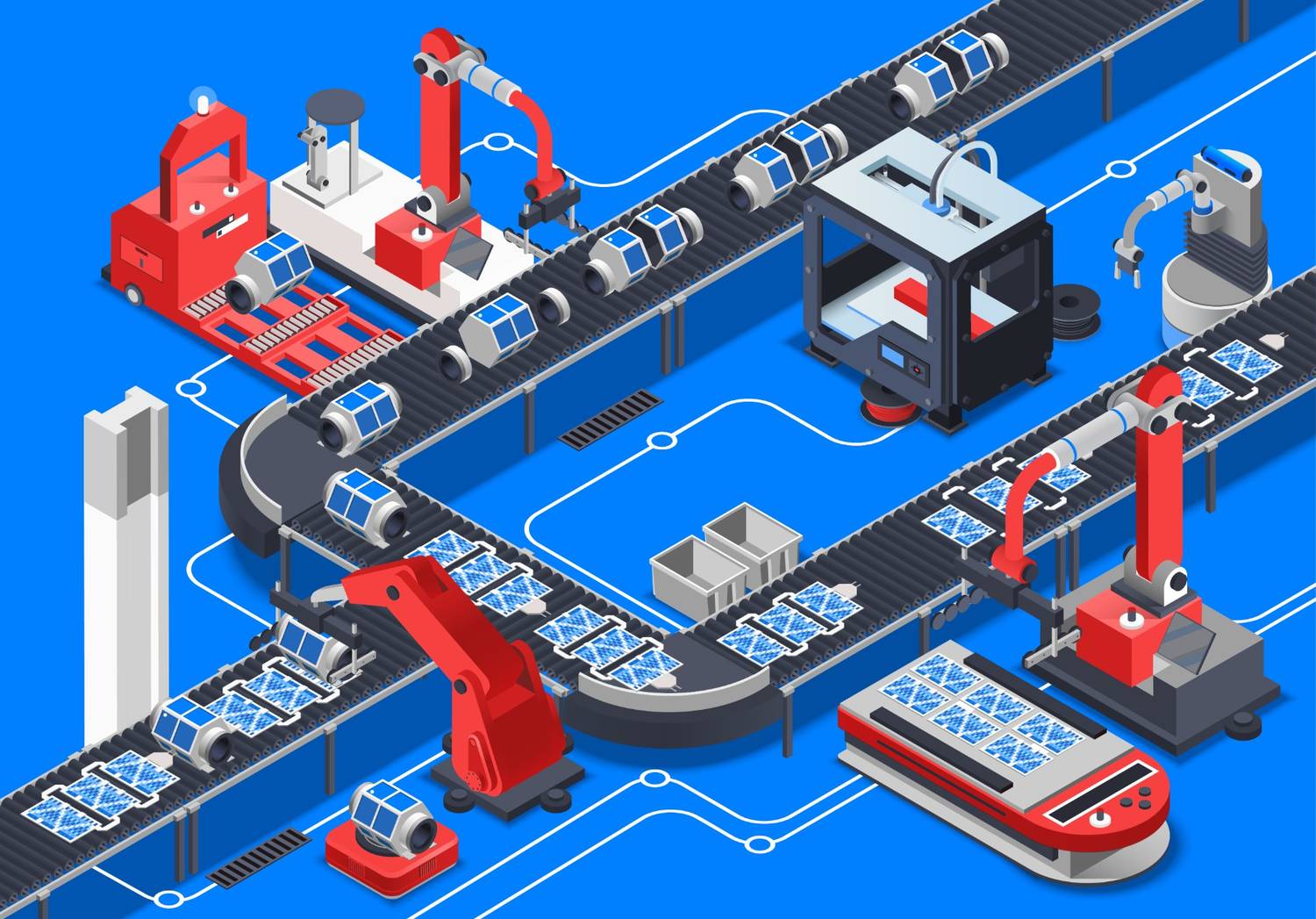

Types of Manufacturing Processes & Spaces Required

Assembly-based manufacturing

Assembly-driven industries such as electronics, appliances, automotive sub-assemblies, and consumer goods generally require lower space per unit of output.

Typical characteristics include:

- Linear or U-shaped assembly lines

- High dependence on manpower or light automation

- Frequent material movement

While machine footprints are small, additional space is required for:

- Work-in-progress buffers

- Operator movement and ergonomics

- Quality check and rework zones

In Indian conditions, assembly plants often require 20–30% additional space beyond machine footprints to ensure smooth flow and avoid congestion.

Machining and Fabrication

Machining-intensive manufacturing such as auto components, engineering goods, and heavy fabrication requires significantly more space.

Here, space is driven by:

- Machine size and service clearances

- Material staging between operations

- Tool rooms and inspection areas

Processes involving CNC machining, welding, and surface treatment also demand isolated zones for safety and contamination control.

As a broad planning indicator, machining facilities typically need 1.5 to 2.5 times the direct machine footprint to operate efficiently without bottlenecks.

Process Industries

In process-driven manufacturing such as chemicals, pharmaceuticals, food processing, glass, and textiles, space requirements are governed less by floor area and more by volume and segregation.

Key space drivers include:

- Utility blocks for boilers, chillers, and compressors

- Raw material and finished goods storage

- Process safety distances and zoning

Vertical space becomes critical, especially where reactors, tanks, or multi-level equipment are involved. In many Indian plants, underestimating utility and service areas leads to cramped layouts and difficult retrofits later.

Warehousing and logistics

Manufacturing does not end at production. Storage and internal logistics consume substantial space.

Indian factories frequently underestimate:

- Raw material holding requirements due to supply variability

- Finished goods storage linked to dispatch cycles

- Aisle widths for forklifts and material handling equipment

As a rule of thumb, logistics and storage can account for 25–40% of total built-up area, depending on inventory strategy and product type.

Ignoring this reality often results in production areas being encroached upon over time.

Utilities, services, and support areas

One of the most common planning mistakes is focusing only on production areas.

Support spaces that must be accounted for include:

- Electrical substations and panels

- Compressor rooms and pump houses

- HVAC plant rooms and duct shafts

- Maintenance workshops and spares storage

These areas rarely generate direct revenue, yet they are essential for uninterrupted operations. In well-planned factories, utilities and services typically consume 10–20% of total built-up area.

This is where early integration of engineering and layout planning makes a measurable difference.

Compliance, Safety, and Circulation Requirements

Indian factories must comply with statutory norms related to fire safety, ventilation, and worker welfare.

This adds space for:

- Fire separation and access routes

- Emergency exits and refuge areas

- Toilets, canteens, and change rooms

These are not optional add-ons. Factories that ignore these requirements at the planning stage often face approval delays or forced design changes during execution.

Planning Space for Expansion

A factory is rarely static. Capacity expansions, product changes, and automation upgrades are inevitable.

Forward-looking space planning allows:

- Expansion bays along production lines

- Oversized structural grids for future equipment

- Clear zones for utility augmentation

This approach avoids land constraints becoming operational constraints. In many Indian industrial projects, lack of expansion planning leads to inefficient vertical additions or external sheds later.

A smoother integration of process planning and master planning can prevent this.

Why Process-led Planning Gives Better Space Outcomes?

The most efficient factories are designed from the process outward, not from the plot inward.

Process-led planning starts with:

- Mapping material flow

- Defining critical adjacencies

- Aligning production, storage, and utilities

This reduces unnecessary circulation, improves productivity, and ensures that every square metre supports operations meaningfully.

This is also where integrated consultants bring value by coordinating architecture, engineering, and process requirements together.

Conclusion

The question is not simply how much space a manufacturing process needs. The real question is how efficiently that space supports production, safety, and future growth.

Well-planned factories use space deliberately. Poorly planned ones spend years compensating for early assumptions.

If you are planning a new facility or evaluating land requirements, realistic space assessment at the concept stage can prevent long-term inefficiencies.