Designing Reliable Utility Systems for Long-Term Manufacturing Performance

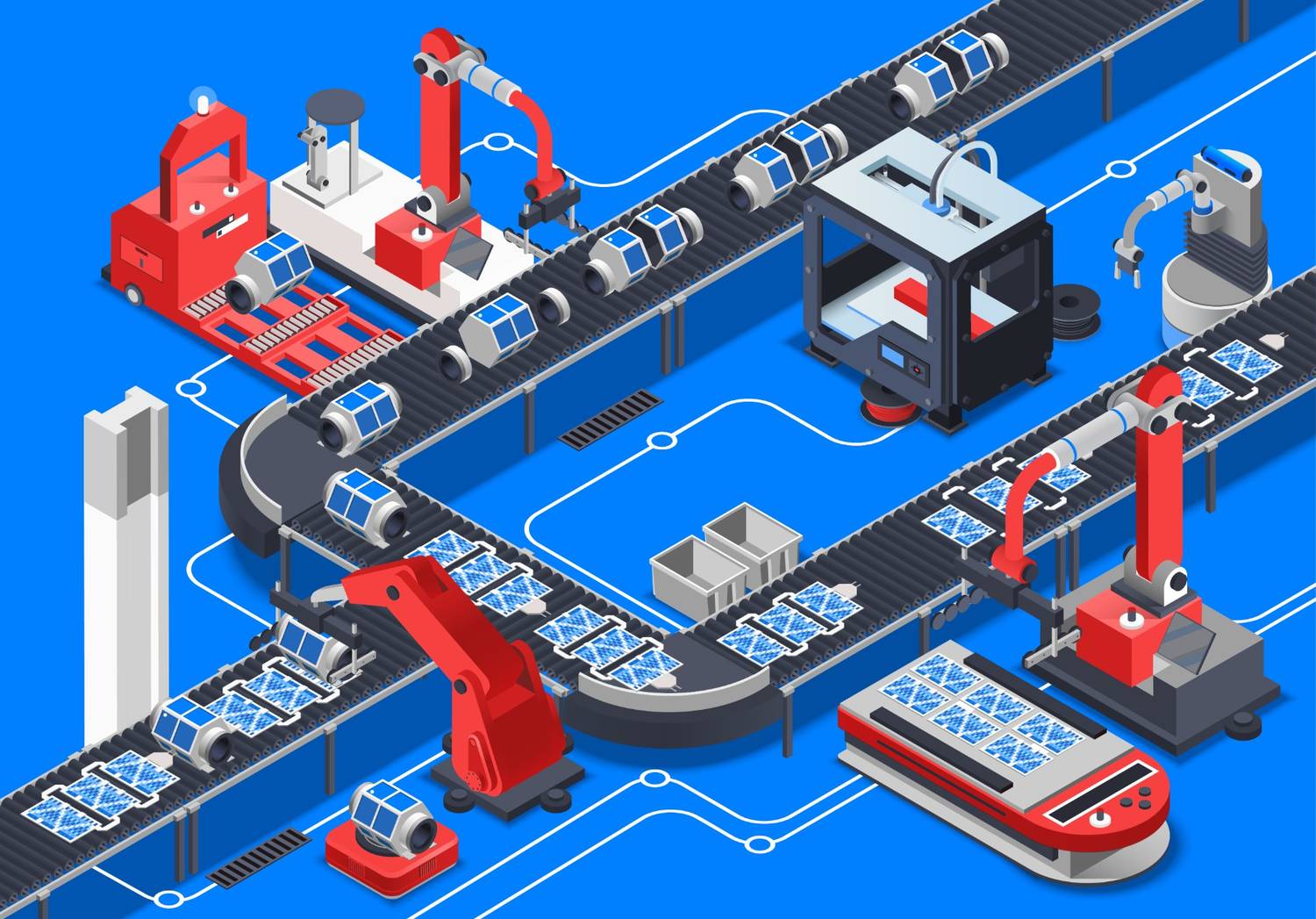

In manufacturing, production equipment often gets the most attention. However, what truly determines whether a factory runs smoothly day after day is the reliability of its utility systems.

Power, water, compressed air, steam, HVAC, and fire protection form the invisible backbone of factory operations. When any one of these systems fails or fluctuates, the impact is immediate like production losses, quality issues, safety risks, and unplanned downtime.

Creating reliable utility systems is not only a technical requirement. It is a strategic decision that directly affects operational continuity, cost control, and long-term scalability of Indian manufacturing facilities.

Why Utility Reliability Is Critical for Consistent Factory Operations

Utilities support every stage of manufacturing, from raw material handling to finished goods dispatch. Unlike machines, utility systems are shared across processes, making them single points of failure.

In Indian conditions, challenges such as grid instability, water scarcity, climate extremes, and fluctuating loads further increase the risk. A well-designed utility system absorbs these uncertainties instead of amplifying them.

Reliable utilities ensure:

- Stable production output

- Consistent product quality

- Equipment protection and longer asset life

- Safer working environments

Understanding Core Utility Systems in a Factory

Most manufacturing plants depend on a common set of utilities, though their scale varies by industry.

Electrical Power Systems

These include grid supply, substations, transformers, panels, and backup power. Voltage fluctuations and improper load distribution remain common issues in many factories.

Water Systems

Process water, cooling water, domestic water, and firefighting demand separate planning. Overdependence on a single source often leads to operational risk.

Compressed Air Systems

Used widely across industries, compressed air quality and pressure stability directly affect machine performance and product consistency.

Thermal Utilities

Boilers, furnaces, and thermic fluid systems are critical in process industries. Poor redundancy planning can bring entire operations to a halt.

What Makes Utility Systems Unreliable in Practice?

Most utility failures are not caused by equipment breakdown alone. They are usually the result of planning gaps.

Common reasons include:

- Underestimation of future capacity requirements

- No redundancy or standby provisions

- Inadequate maintenance access and layouts

- Utilities designed in isolation rather than as an integrated system

In many Indian factories, utilities are added incrementally as production grows, leading to inefficiencies and operational stress.

Designing Redundancy Without Overengineering

Reliability does not always mean oversizing. It means designing smart redundancy.

Critical utilities such as power supply, compressed air, and cooling should follow an N+1 philosophy, where one additional unit supports operations during maintenance or failure.

For example:

- Dual transformers instead of one oversized unit

- Standby air compressors for critical lines

- Multiple water storage zones instead of a single tank

Such configurations reduce downtime risk while keeping capital costs under control.

Planning Utilities for Indian Operating Conditions

Indian factories face unique challenges that global design templates often overlook.

High ambient temperatures increase cooling and HVAC loads. Dust levels affect electrical and mechanical equipment. Seasonal water availability varies significantly across regions.

Guidelines and efficiency benchmarks from the Bureau of Energy Efficiency emphasise designing utilities that perform reliably under local conditions, not just under ideal assumptions.

This makes climate-responsive design and material selection essential for long-term stability.

Integration of Utilities With Plant Layout and Process Flow

Utility reliability is strongly influenced by layout decisions.

Poor routing of pipelines and cables increases pressure drops, energy losses, and maintenance difficulty. Crowded utility corridors complicate fault isolation and repairs.

An integrated approach aligns:

- Process equipment placement

- Utility corridors and service floors

- Maintenance access and safety clearances

When utilities are planned alongside architecture and engineering, reliability improves without increasing complexity.

Monitoring and Control as Reliability Tools

Modern factories increasingly rely on monitoring systems to prevent failures rather than react to them.

Energy meters, pressure sensors, flow monitoring, and automated alarms help identify deviations early. This is particularly important in utilities like compressed air and steam, where small inefficiencies compound into large losses.

According to the Central Electricity Authority, industrial facilities that actively monitor load behaviour experience fewer electrical failures and better demand management.

Data-driven utilities are no longer optional for large manufacturing setups.

Why Utility Planning Must Start at the Concept Stage

Retrofitting reliability into existing utility systems is expensive and disruptive. The most effective time to address reliability is during the concept and master planning stage.

Early-stage decisions define:

- Capacity buffers for future expansion

- Location of utility blocks and service zones

- Integration of renewable and backup systems

This approach reduces lifecycle costs while improving resilience and scalability.

Conclusion

Consistent factory operations depend as much on utilities as on production equipment. Reliable utility systems protect productivity, quality, and safety in an increasingly competitive manufacturing environment.

For factory owners and project teams, utilities should not be treated as secondary services. They are core infrastructure that determines how smoothly a plant performs over decades.