Impact of PLI (Production Linked Incentive) Scheme on Electronics Manufacturing

India’s electronics manufacturing sector is undergoing a transformation, with Production Linked Incentive (PLI) at its core. Launched to boost domestic production and reduce import dependency, the scheme is now driving large-scale investments, job creation, and global competitiveness.

For businesses planning to set up an electronics manufacturing plant, understanding the impact of the PLI scheme is essential—not just for eligibility, but for long-term strategic planning.

What Is the PLI Scheme and Why Does It Matter?

The PLI scheme offers financial incentives to manufacturers based on incremental sales and production. It’s designed to attract both domestic and foreign investment, promote innovation, and strengthen India’s position in global supply chains.

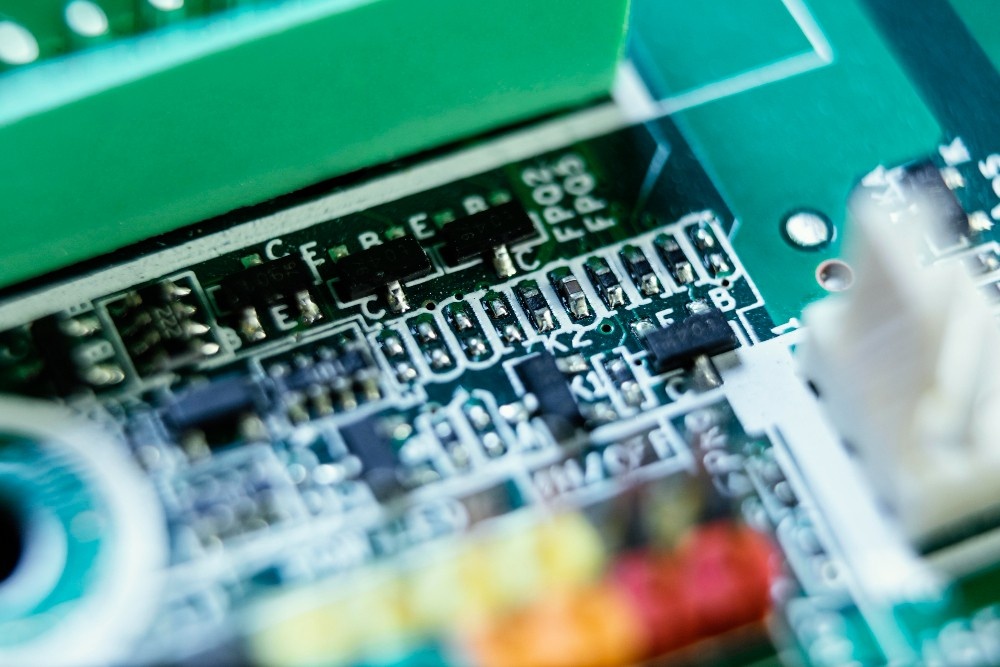

In the electronics sector, the scheme covers mobile phones, electronic components, semiconductors, and display modules. The latest expansion includes a ₹22,919 crore outlay specifically for core components like PCBs, passive parts, and subassemblies.

How Has the PLI Scheme Impacted Electronics Manufacturing?

Since its launch, the PLI scheme has catalyzed over ₹1.46 lakh crore in investments and generated exports worth ₹4 lakh crore. Smartphone exports alone crossed ₹1 trillion in just five months of FY26, with Apple, Foxconn, and Tata Electronics leading the charge.

The scheme has also helped shift India’s role from an assembly base to a design-led manufacturing hub. New incentives now reward quality benchmarks and indigenous innovation, pushing manufacturers to invest in R&D and advanced technologies.

What Does This Mean for New Facility Setups?

If you’re planning to set up an electronics manufacturing plant, the PLI scheme can significantly influence your factory setup budget and operational strategy. Here’s how:

1. Capital Subsidies and Incentives

The scheme offers up to 25% capital subsidy for eligible investments in equipment and infrastructure. For turnover-based incentives, companies can earn 1% to 10% on incremental sales depending on the product category.

2. Lower Entry Barriers for MSMEs

Startups and mid-sized firms can benefit from relaxed investment thresholds and additional incentives for employment generation. This opens doors for smaller players to enter high-tech manufacturing.

3. Faster ROI and Scalability

With incentives linked to production, companies can recover setup costs faster. This encourages scalability and phased expansion, especially in electronics clusters like Noida, Chennai, and Pune.

VMS Consultants offers specialized electronics manufacturing plant facility setup services, helping businesses align their infrastructure with PLI eligibility and operational efficiency.

What Are the Eligibility Criteria?

To qualify for the PLI scheme, companies must:

- Be registered in India

- Manufacture goods under the specified target segments

- Meet minimum investment and turnover thresholds

- Submit a detailed project report and audited financials

For example, a PCB unit may need ₹50 crore in investment and ₹75 crore in turnover to qualify. The application process includes documentation like UDYAM registration, IEC code, and net worth certificates.

How to Align Your Facility Design with PLI Goals

1. Focus on Value Addition

Design your facility to support in-house component manufacturing, testing, and packaging. This increases domestic value addition and improves your incentive eligibility.

2. Plan for Automation and Quality Control

Incentives are now tied to Six Sigma standards and design-led manufacturing. Integrate smart systems, cleanrooms, and quality labs into your layout.

3. Choose the Right Location

Electronics clusters offer better infrastructure and policy support. States like Tamil Nadu and Karnataka provide land subsidies, power rebates, and fast-track approvals.

VMS Consultants can help you evaluate site options and design facilities that meet both operational and compliance needs.

What Are the Latest Updates You Should Know?

- The government recently approved a ₹22,919 crore PLI scheme for electronic components, expected to generate ₹4.56 lakh crore in production and 91,600 direct jobs.

- Apple’s iPhone 17 lineup is now fully manufactured in India, showcasing the scheme’s success in attracting global giants.

- The scheme is evolving to include design and innovation incentives, not just production volume.

Take the Next Step Toward Smart Manufacturing

The PLI scheme is more than a subsidy—it’s a strategic opportunity to build future-ready electronics manufacturing facilities in India.

With the right planning, design, and execution, businesses can unlock long-term growth and global competitiveness.